SANDURA FAQ’s

Sandura® represents our brand of products, which assures the highest quality and standards in the industry.

The standard sizes are as follows:

Butt Thickness – 7/16″, 5/8″and 3/4″

Width – 3” to 9” (average 6”)

Length – 18” and 24″

Unlike cedar shingles, our hardwood shingles do not expand or swell with moisture; therefore, not much spacing is required. Spacing between adjacent shingles (joints) should be a minimum of 1/8” and a maximum of 1/4”. View installation guide.

A square simply refers to the amount of shingles necessary to cover 100 square feet of exposure.

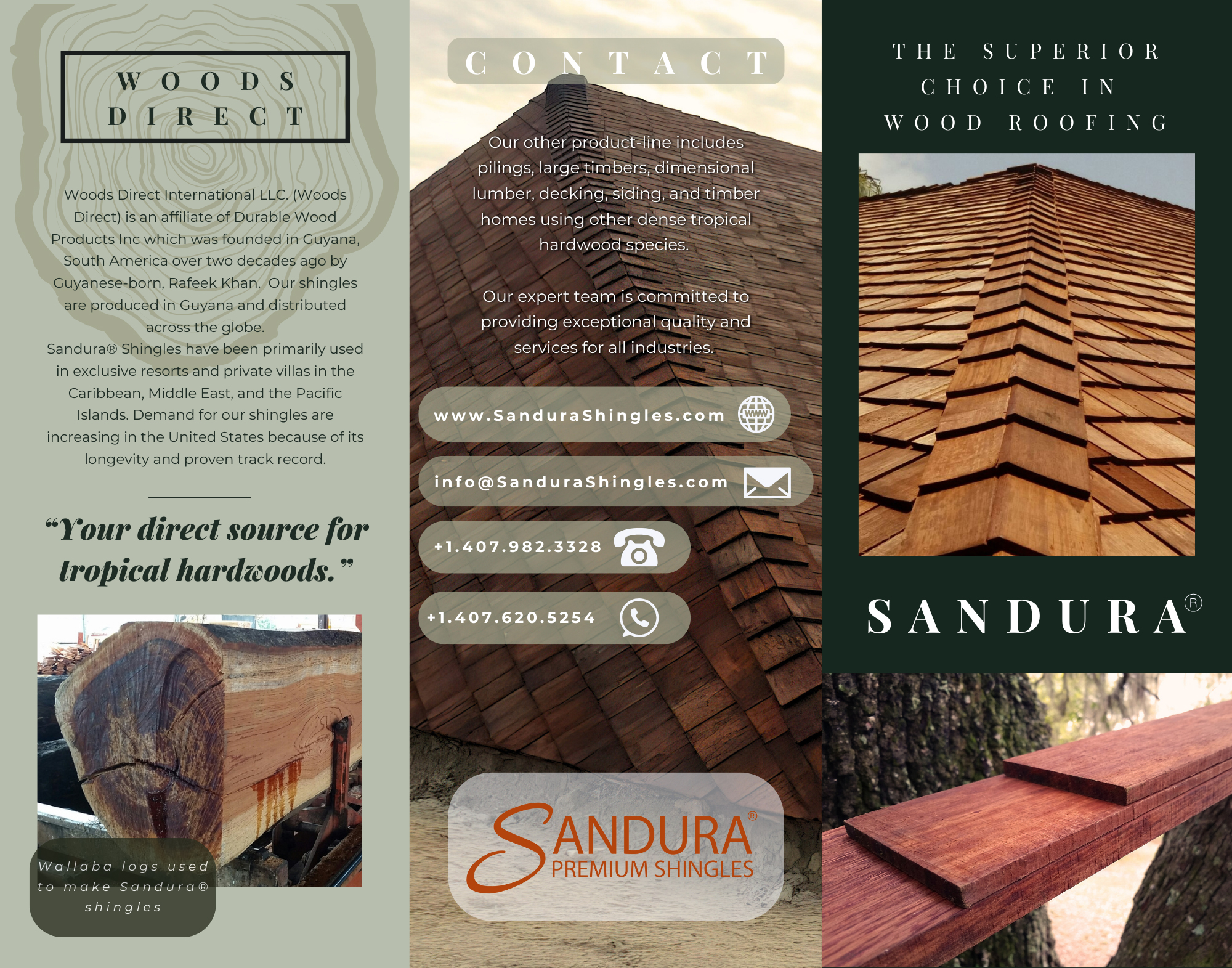

Wallaba shingles are naturally resistant to insect infestation, moisture and decay and are known to last for over 50 years.

When properly installed, our shingles can resist winds over 180 mph and have proven itself time and time again, withstanding even category 5 hurricanes.

View testimonials from customers whose shingles survived hurricane Irma.

Sandura® shingles are made from a tropical hardwood known as Wallaba, which is harvested in South America.

As the wood ages it turns into a beautiful Pantina Grey, which provides a reflective surface on roofs acting as an insulator that repels solar heat and saves energy.

Typically, there is little or no maintenance required. However, if your roof is under shady areas you can anticipate the need some cleaning.

Sandura® Shingles is a natural product, which requires no treatment.

Yes, Sandura® Shingles come with a standard 25 year warranty. View warranty.

Tapersawn shingles used for the general roof coverage, while ridge cap shingles are used specifically for the ridge of the roof. Unlike tapersawn shingles which have random widths (3” – 9”), ridge cap shingles have fixed widths of 4” and 5” only.

Also, ridgecap shingles are slightly thicker than the general tapersawn shingles.

- The enhanced production techniques for Sandura® Shingles there is less waste of forest resources, creating greater sustainable harvesting and reducing negative effects on the rainforest environment.

- The innovative technology used in the manufacturing of Sandura® is safer for our experienced craftsmen.

- Sandura® offers consumers a wider range of shapes and styles.

- Sandura® Wallaba Shingles provide more uniform cuts with a lower manufacturing carbon footprint.

Traditionally, standard hammer and nail have been used. However, to minimize labor, pneumatic tools are encouraged. We have had much success using the Hitachi coil nailer – NV 45AB2, or similar.

- Typically we recommend using 1-1/2 to 1-3/4” x .090 Ring Stainless.

- However, depending on the environment, some users have found success using Hot Dip Galvanized Common Nail 1-1/2” to 1-3/4”.

- We also have some users who prefer to use 304 Stainless Steel Staples – Medium Crown N17 1-1’2” X 16GA. X 7’16” Crown.

The most important factor is that the nails are rust-resistant.

Our wallaba hardwood shingles can we shipped to any destination, worldwide.

Presently, the shingles are stocked at our factory in Guyana and distribution locations in the United States of America, Mauritius, Jamaica and Holland.

In order to purchase, you must first determine the Square feet or Square meter of your roof coverage and submit this information and other details by filling out our Order Form or contact our nearest dealer.

Electronic wire transfer is our preferred payment method.

Left natural, wallaba shingles will change color and will gradually become grey over 2-3 years. This change of wood color comes as a natural function caused by sun (UV rays), rain, wind, and thaw. Preserving the wallaba’s natural color is possible with a clear oil coating but there is a significant drawback to this – treated wood won’t breathe the same and will deteriorate quicker.

Left natural, wallaba shingles will change color and will gradually become grey over 2-3 years. This change of wood color comes as a natural function caused by sun (UV rays), rain, wind, and thaw. Preserving the wallaba’s natural color is possible with a clear oil coating but there is a significant drawback to this – treated wood won’t breathe the same and will deteriorate quicker.

The answer to this question depends on the look you wish to have for your house. There are stains available but we recommend going the natural route with this beautiful product.

Sandura® Shingles can take stain well. However, like your skin wood needs to breath and we recommend allowing the shingles to first weather naturally and then paint to your desire color.

It is possible to paint shingles to your desired color. For best paint result, wait for a few months for the shingles to change its natural color before painting.

2 nails per shingle.

Good air space behind all siding products is essential and can be achieved in a variety of ways. Wooden laths or a ventilation membrane are two options to keep an air space. These materials allow trapped moisture a way to drain out. They also allow drying of both the shingles and the underlayment.

At our company we firmly believe that by employing sustainable forest management practices, watershed protection, and ecologically responsible harvesting processes we can utilize forest products without depleting precious natural resources. All trees harvested for the manufacturing of Sandura® Wallaba Shingles are certified by Guyana Forestry Commission (GFC). The GFC safeguards against Guyanese forest exploitation and ensures that timbers are legally sourced according to international sustainable forest management standards. Information for Guyana Forestry management can be found here: https://forestlegality.org/risk-tool/country/guyana

No, the natural oils and extractive content found in Sandura® Shingles protect them from the devastating effects of insects, fire, and fungi.